Advanced Solid Modelling - Pipe Riser Inspection Tool

In my graduate course on solid modeling and mechanics, we learned the various ways to use 3D engineering CAD software (specifically SolidWorks) to create well-designed and well-dimensioned parts. By applying what was already known about materials science and mechanics, we dove into the realm of finite element analysis and how the software can aid in making determinations for the part.

The class covered many different manufacturing techniques and general rules of thumb for making parts that are actually manufacturable using standard industrial processes. In this way, we became more familiar with how metal parts are manipulated, which aided in the design of our own parts.

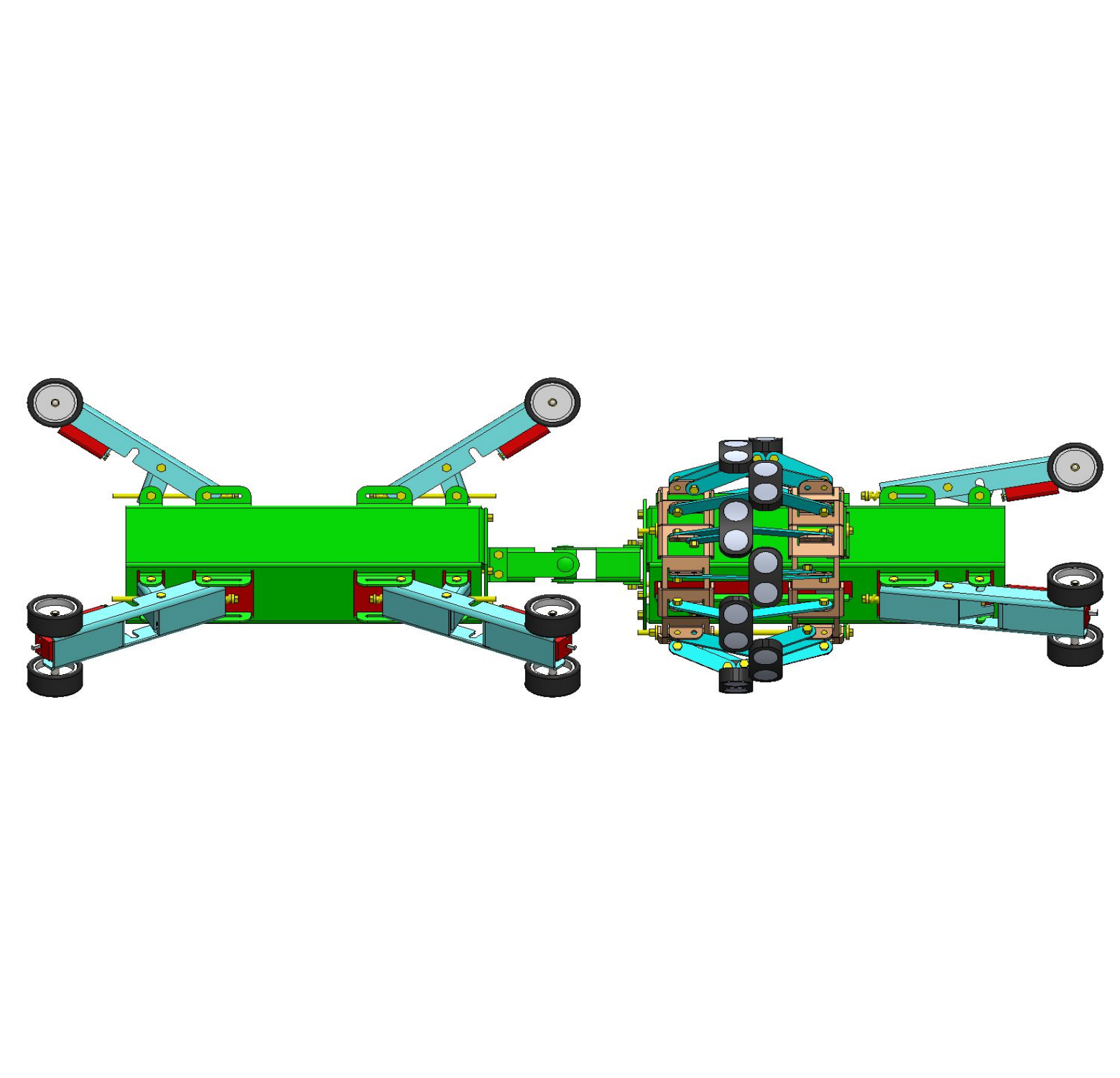

For our final project, my team was tasked with designing a flexible pipe riser inspection tool with a focus on manufacturability using the methods taught in the course. My team developed a design that is almost entirely manufactured using bent sheet metal. The design and analysis are outlined in our final report.